Image Recognition

Product Setup Requirements

What information is required for SKU setup?

- Minimum 5 Megapixel images of product packaging from all angles

- For cylindrical products:

- 3-4 images around the circumference

- 1-2 images from the top

- Complete packaging information including branding and color for visual representation

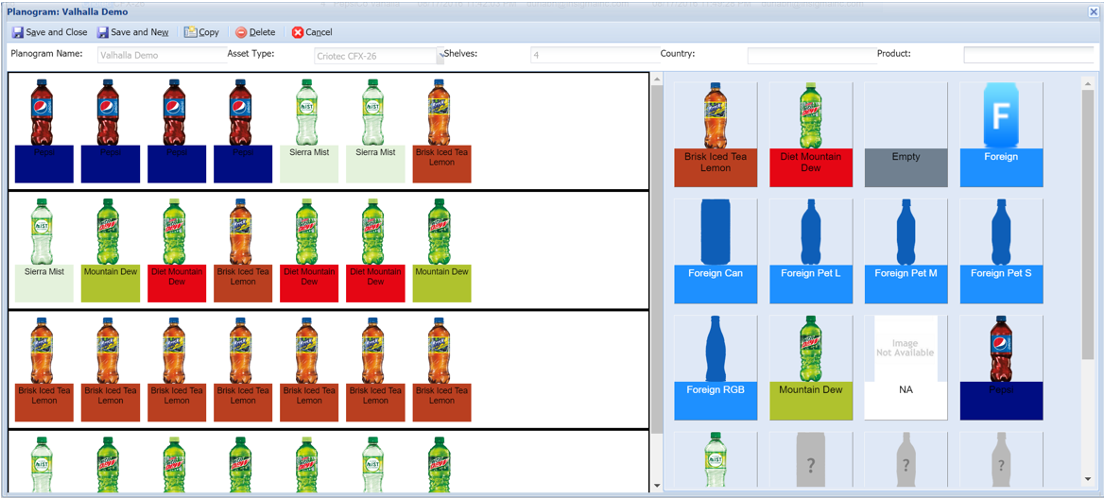

Planogram Management

How many planograms are typically needed?

A market usually requires only a small number of planograms. These are defined based on combinations of:

- Market

- Channel

- Classification

- Equipment type

For example, a single market might have different planograms for:

- Highway-adjacent stores

- City center locations

What information is needed for planogram setup?

To create a planogram, you need:

- Complete product setup

- Shelf specifications

- Asset type details (if planogram is specific to certain cooler/freezer models)

Who can manage planograms?

Any user with planogram modification privileges can:

- Create new planograms

- Assign planograms to assets

Priorogram System

What is a priorogram?

Priorogram is Coolr's proprietary approach to handling "missed opportunities" and "order recommendations" for out-of-stock situations. This system was developed to address common challenges with traditional planograms:

- Traditional planograms can be tedious to set up

- Field implementation often deviates from defined planograms due to practical constraints

The priorogram model allows customers to:

- Specify SKUs in order of priority

- Focus on product availability rather than specific positioning

- Receive recommendations based on priority list and current inventory

Stock Calculation Methods

How is stock calculated across different tiers?

Basic Tier/Navigator

- Uses Share of Shelf (SoS) or Share of Visible Inventory (SOVI)

- Common approach among traditional image-based monitoring solutions

Commander and Pioneer Tiers

- Utilizes depth estimation for stock calculation

- Stock levels are approximated in 25% increments (25%, 50%, 75%, 100%)

- Camera positioning affects measurement:

- Horizontal freezers: Top-mounted camera provides accurate stock level assessment

- Vertical freezers: Front-mounted camera measures stock by product distance from shelf front

How accurate is stock calculation?

- Approximately 95% accurate across 30,000+ units

- Successfully used for order recommendations across various businesses

- Proven track record of 30%+ sales uplift in first year when recommendations are followed

Can exact stock counts be obtained?

While Coolr's solution prioritizes cost-effectiveness and quick ROI with 95%+ accuracy, alternative solutions for exact counting include:

- Grab 'n Go systems

- Just Check Out

- Weight sensors

- RFID technology

Key Metrics and Calculations

What are the key performance metrics?

Stock (SOVI - Share of Visible Inventory)

- Used to identify:

- Replenishment schedules

- Product sale patterns at SKU level

Planogram/Priorogram Compliance

- Measures:

- Product portfolio effectiveness

- SKU-level placement efficiency

- Out-of-stock situations

- Product distribution

Purity

- Measures percentage of customer's own products in an asset

- Also known as Share of "own" inventory

- Used for trade terms compliance monitoring

How are metrics calculated?

Standard calculations include:

Stock % = (Total Visible Products - Foreign Products) / Total Available Positions

Purity = (Total Visible Products - Foreign Products) / Total Visible Products

Planogram Compliance = (Total Planogram Facings - Compliant Facings) / Total Available Positions

Note: Total Available Positions is determined by either:

- Defined planogram occupied spaces

- Or (Shelves × Columns per shelf) as specified in Asset Type configuration

Image Recognition Process

What is Coolr's image recognition workflow?

-

Image Processing

- Stitching of fragmented images

- Human feature obfuscation

- Area of interest cropping

- Perspective correction (fish-eye reduction)

- Quality adjustment (brightness, contrast)

-

Detection Steps

- Shelf/basket identification

- Product shape detection

- Empty space recognition

- SKU identification

- Stacking analysis

- Stock level assessment

What is the accuracy level and how is it maintained?

- 95%+ accuracy in automated recognition

- Verification process:

- Random 20% of images undergo human review

- Minimum 10 SKUs per test set

- Regular benchmarking across 1,000 images

- Diverse location/asset sampling

Why is continuous training necessary?

Image recognition, like human learning, requires ongoing training to handle:

- Seasonal packaging changes

- New product variants

- Similar product differentiation

- Image quality variations

- Product placement variations

The system must continuously learn to:

- Distinguish between similar products

- Recognize new packaging designs

- Adapt to different viewing angles

- Handle varying light conditions

- Process multiple product variations

Business Applications

What are the key use cases for this data?

- Inventory optimization

- Improved on-shelf availability

- Portfolio optimization

- Merchandising management

- Standards monitoring and enforcement

- Cost and carbon footprint reduction

- Compliance

- Trade terms enforcement

- Unbiased continuous monitoring

- Business optimization

- Missed opportunity identification

- Delivery routing optimization